- #SOLIDWORKS FLOW SIMULATION CHECK GEOMETRY VERIFICATION#

- #SOLIDWORKS FLOW SIMULATION CHECK GEOMETRY WINDOWS#

If it's a single part, use a cut command to cut away most of the model and try the same process.Overhyped, but a Good Value in the Right Situation When it stops working, you've found your problem part. Then, incrementally add things back, re-running as you add each set of few parts. Delete all but one part in the model, set up a basic analysis, and see if you can get it to launch the solver and mesh. If none of that works, the sure-fire way to solve this is to simplify your model to the point where it works. Make sure that message hasn't popped up in the background

#SOLIDWORKS FLOW SIMULATION CHECK GEOMETRY WINDOWS#

If you're pegging out your memory, you may need to simplify the mesh or the model.Īnd a last potential one, on your first analysis on a new computer the solver process (efdsolver.exe) can often throw up a Windows error asking for permission to execute. Through Task Manager, check your computer's resources as you launch the solve.

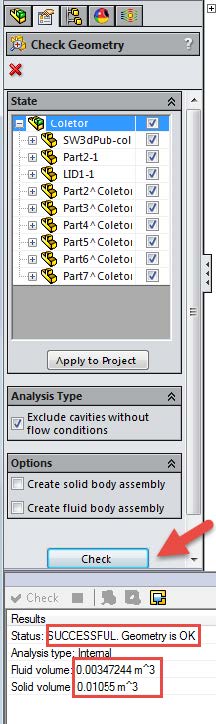

In the Flow Simulation check geometry tool, make sure the fluid volume looks like the area you're planning to analyze - it could be picking up the wrong volume.

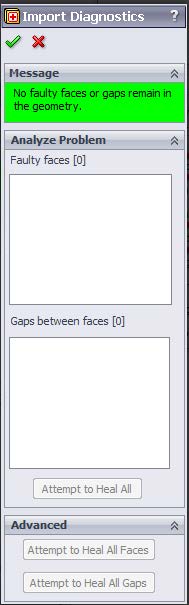

Manager, or under Tools > Interference Detection (at the Assembly level).Ī couple of things to look at - try setting the mesh resolution to a really low level - it might be getting hung up on preparing to mesh. This tool can be found in your Evaluate tab on the Command Should be on is the “Include multibody part interferences” (don’t want toįorget those). Material interferences, all sets of touching faces. Having this checkbox on will list, in addition to any This is where the “Treat coincidence as interference”Ĭheckbox comes in. Level). very important that the faces that you think are touching, areĪctually touching. Flow Simulation is not as concerned with interference, but if youĪre doing heat conduction problems it is found in your Evaluate tab on theĬommand Manager, or under Tools > Interference Detection (at the Assembly Interference detection is a very useful tool for Simulation as well as Flow This tool can beįound with the Flow Simulation add-in turned on under Flow Simulation > You are going to need if you are doing an internal analysis. This tool will also check if you have a fully enclosed fluid volume, something Certain invalid contacts can be fixed by this tool,īut it is a good idea to fix these yourself before proceeding any further. This is a great way to find out if you have any invalid contacts that Flow This tool can beįound at the part or assembly level under Tools > Check. Tool is especially helpful when you have imported geometry. This is a really simple tool for checking for invalid faces and edges. When this option is turned on, features that cause invalid geometryįail. This setting checksĮvery feature against all existing faces and edges, not just adjacent facesĪnd edges. Depending on the file, this may take a while.

#SOLIDWORKS FLOW SIMULATION CHECK GEOMETRY VERIFICATION#

System Options Tab > Performance Section > Verification on RebuildĬheckbox, make sure this is checked, exit out of the options, and pressĬTRL-Q. I tend to do this as soon as I open the file. List of things I do before creating a newįorce Rebuild with Verification on Rebuild (VOR) turned on When you've already put hours and hours into an analysis. I’ve found that if I do this early, it tends to minimize headaches Group, I've developed a to-do list before I start any Flow SimulationĪnalysis.

0 kommentar(er)

0 kommentar(er)